So you’ve got the woodworking bug and you’re feeling a strong urge to whittle some wood and get down and dusty with a flute kit. We’re here to help.

We offer two flute making kits, the Pre Bord Kit is a great choice for more advanced woodworkers who have more tools and equipment, and the Pre Tuned Kit is perfect for everyone else. Follow all steps if you have a Pre Bored Kit or skip to steps 4 and 6 if you have a Pre Tuned kit.

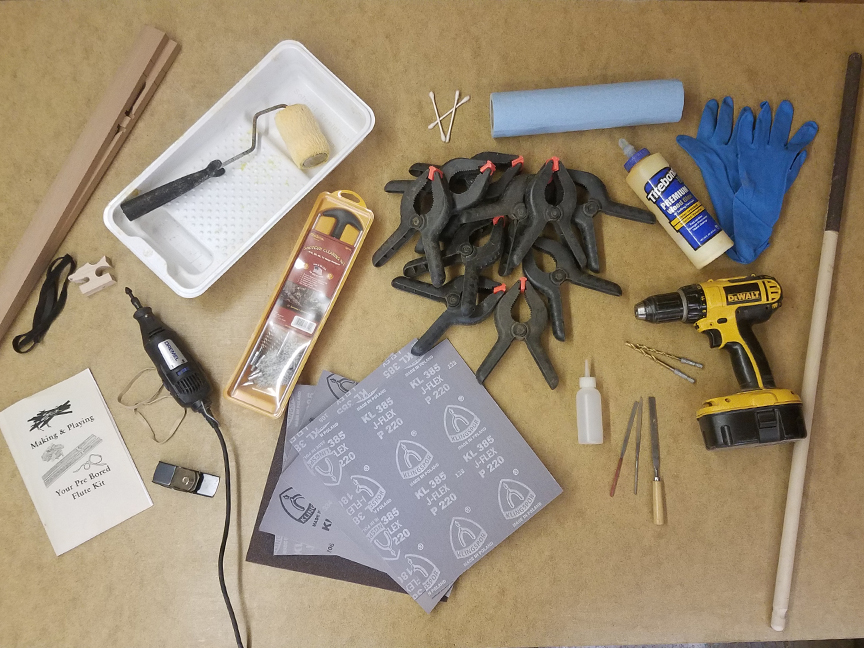

Supplies list for Pre Tuned Flute Kit

- A nice sharp plane for shaping . Other options include a belt sander, lathe, router, carving knife, or sandpaper.

- Sandpaper in 60, 80, 100, 120, 150, 180 and 220 grits

- Gloves for applying varnish

- Shop paper towels

- paint brush

- varnish of your choice ( we use oil based polyurethane)

Supplies list for Pre Bored Flute Kit

- A drill with both a 3/16” bit and 1/4”bit

- Small files

- Titebond II wood glue by Franklin

- A glue applicator like a small paint roller or a small foam “brush”

- About 10 pinch clamps

- A swab to reach up into the flute to remove glue that extrudes after clamping. A shotgun swab with a paper towel attached works well.

- Sandpaper in 60, 80, 100, 120, 150, 180 and 220 grits

- A nice sharp plane for shaping and removing dried glue. Other options include a belt sander, lathe, router, carving knife, or sandpaper.

- A few sturdy rubber bands

- An electronic tuner

- A ¾ inch dowel with 60 grit sandpaper glued to it to sand the inside of the flute.

- Dremel with cone-shaped grind stone or anything that can be used to gradually burn the fingering holes larger.

- A small squeeze bottle for applying varnish inside the flute

- Gloves for applying varnish

- Shop paper towels

- Oil based polyurethane varnish

- measuring tape

STEP 1 | Gluing and clamping

Supplies: Foam roller and paint tray, Titebond II glue, swab (shot gun swab pictured here), q-tips, water for clean-up, 10 pinch clamps

Optional: Gloves

Glue the flute blank halves together using Titebond II wood glue and a roller :

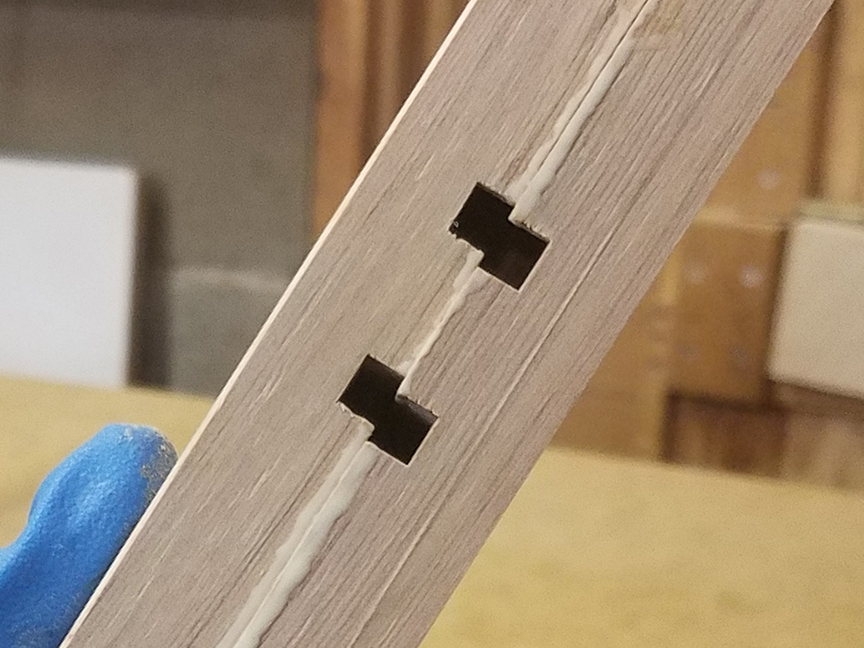

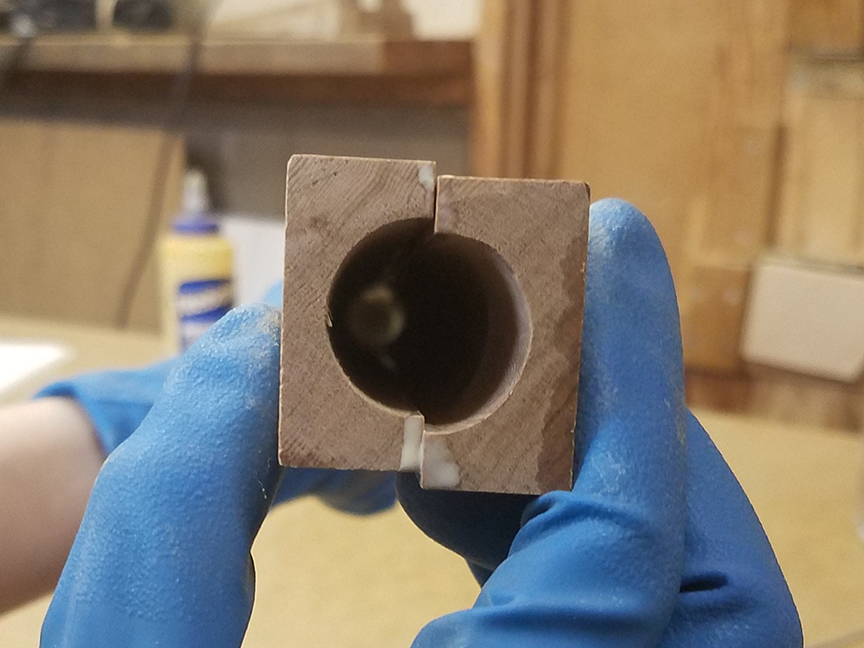

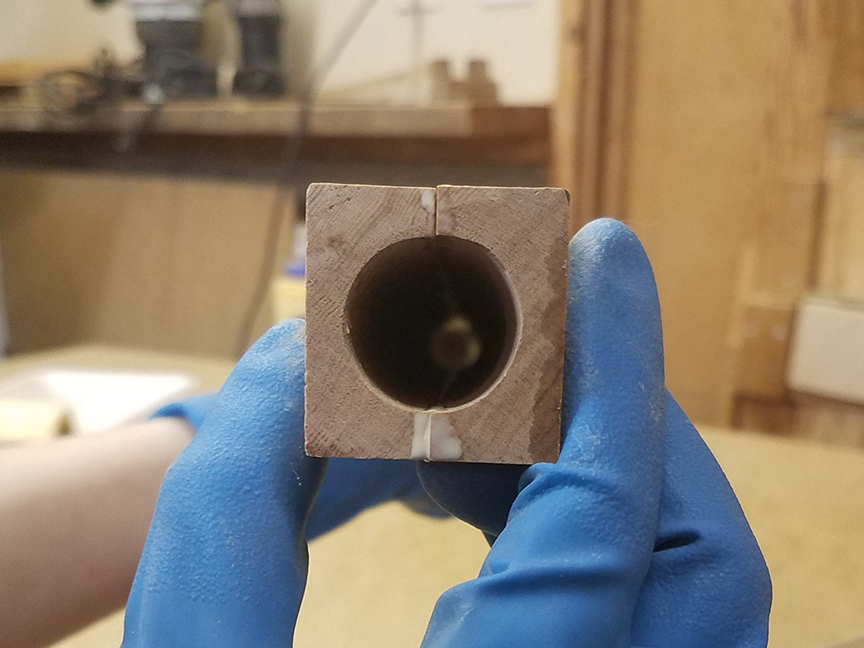

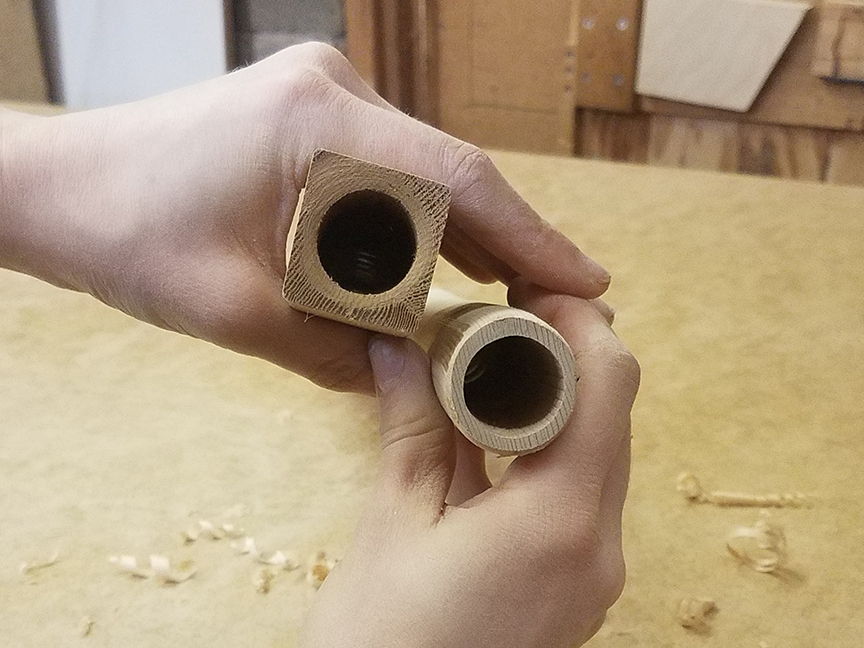

Line up the fipple holes and bore of flute

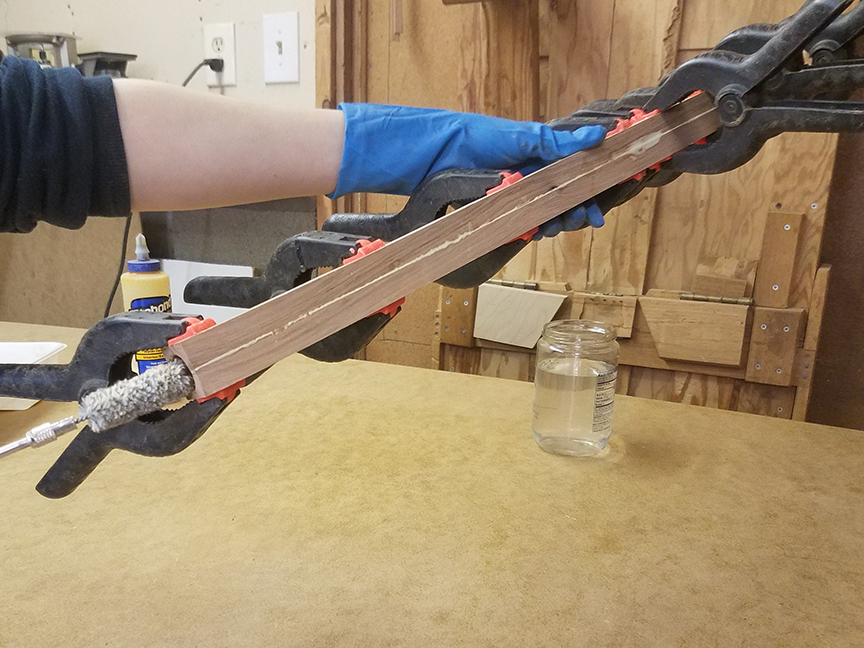

Once the fipple holes and the bore of the flute are aligned, use two clamps as shown to hold the flute while placing the other clamps.

Use 10 pinch clamps, four along the body and six from the fipple holes to the blow hole end. Note how I place these six clamps so that they put even pressure on the end of the flute.

Double check that everything is still aligned, if the flute halves have shifted, unclamp and realign.

Swab the excess glue from the bore using a gunshot swab ( or similar tool of your making) and swab the fipple holes using a q-tip. It is not important to swab the slow air chamber.

Once the glue is dry ( usually within a few hours) it is safe to remove the clamps. Un-clamp and sand your flute blank.

You will now need to sand the outside of the flute until it is smooth and square using a belt sander, sandpaper or a plane. I would recommend using an 80 grit belt.

STEP 2 | Refining the fipple holes and enlarging the blowhole

Supplies: metal files, drill with 1/4 inch bit

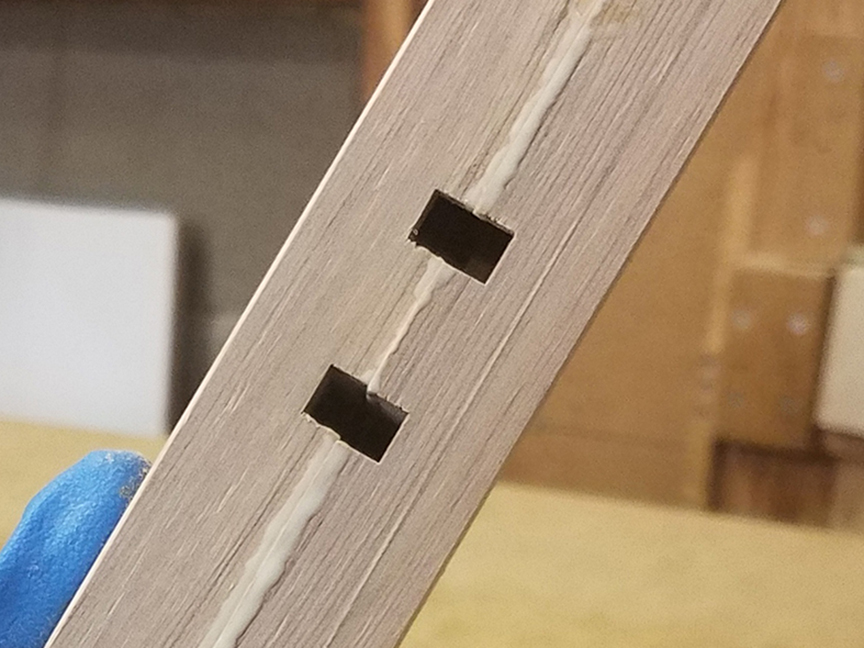

Using a coarse flat file, sand the fipple holes, correcting any misalignment that may have occurred in gluing. Sand off any dried glue and use the file to smooth and even out the internal ramps.

Now make external ramp

Use a ¼” drill bit to enlarge the blow hole. Place mouth over top fipple hole and blow out the debris from drilling the hole, you can also use a rat tail file to smooth the blow hole. Always blow the flute out after drilling.

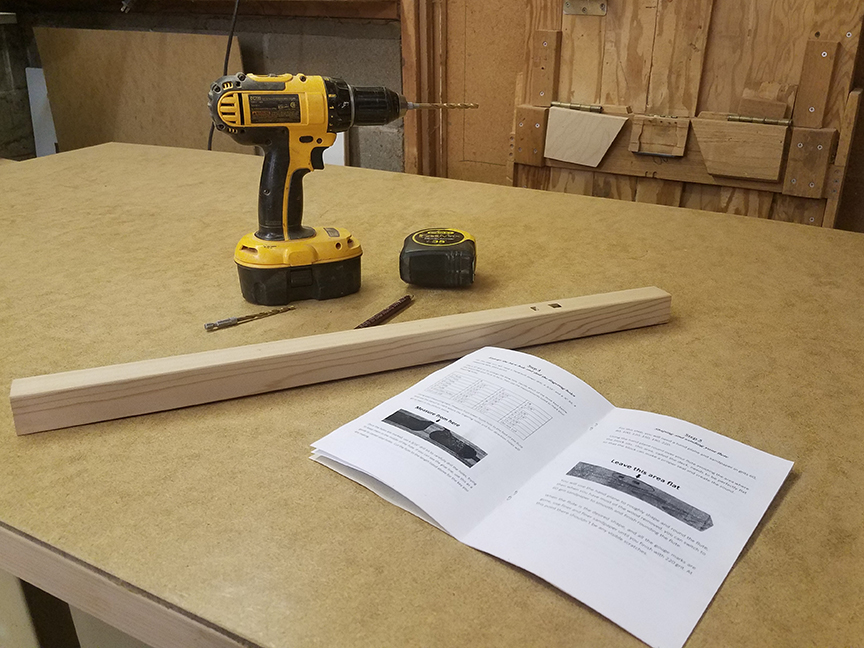

STEP 3 | Drilling the fingering holes

Supplies: flute blank, mesuring tape, drill with 3/16 inch bit, pencil, Pre Bored Kit instructions

Decide which key you would like your flute to be in and mark the fingering holes using the measurements given. Measure from the back edge of the front fipple as shown

Use a 3/16” bit to drill the holes, for best results mark a center line so your holes come out straight. We use a drill press.

STEP 4 | Shaping and sanding your flute

Supplies: Hand plane, sandpaper in grits 60, 80, 100, 120, 150, 180 and 220

Optional: Dust mask

Using a hand plane shave wood away starting with the corners of the flute and avoiding the area where the block sits.

I like to shape the lower body of the flute first, holding the square flute at an angel and shaving down the corners towards the foot of the flute. If you are shaping a Pre Tuned Kit, don’t carve over the fingering holes or four direction holes. This area will be shaped with sandpaper only because changing the wall thickness over the fingering holes will change the tuning.

When you are ready, turn the flute around and shave downward towards the mouth end, taking small passes to taper the end to the desired shape.

Check the bore end and mouth end regularly to make sure you are achieving a nice cemetrical shape

Don’t worry too much about achieving a smooth surface yet, the shaping will continue with the coarsest sandpaper.

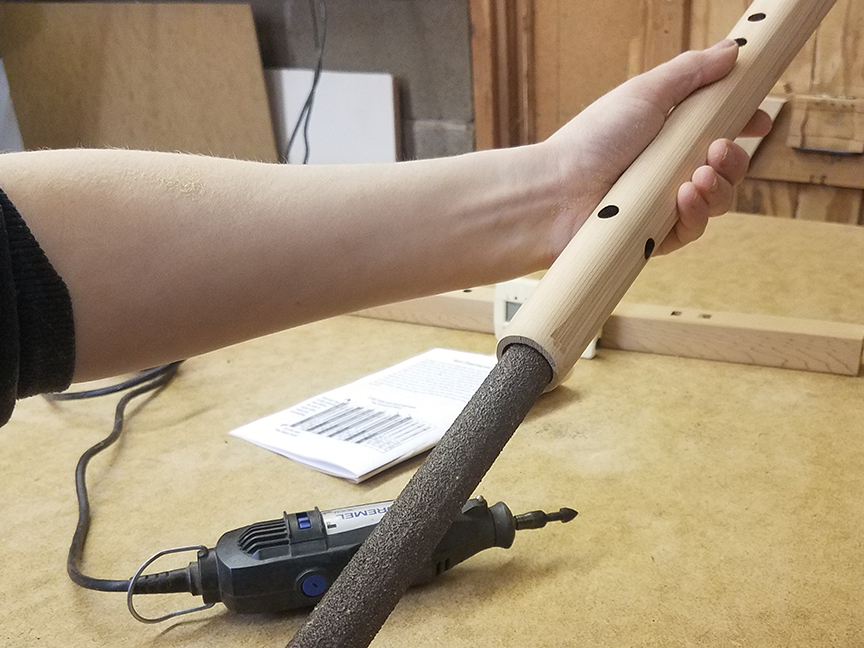

Using 60 grit sandpaper, continue to shape your flute. Sand until all gouge marks are removed and the flute is nicely rounded. I like to hold the sand paper like this:

Move through the sandpaper grits as follows 60, 80, 100, 120, 150, 180, 220. Each grit will remove the scratches from the previous grit, don’t be too hasty! You want to get all the scratches out before varnishing.

Use a flat surface and 220 grit sandpaper to sand the flat sides of the flute until they are smooth and scratch free.

STEP 5 | Tuning

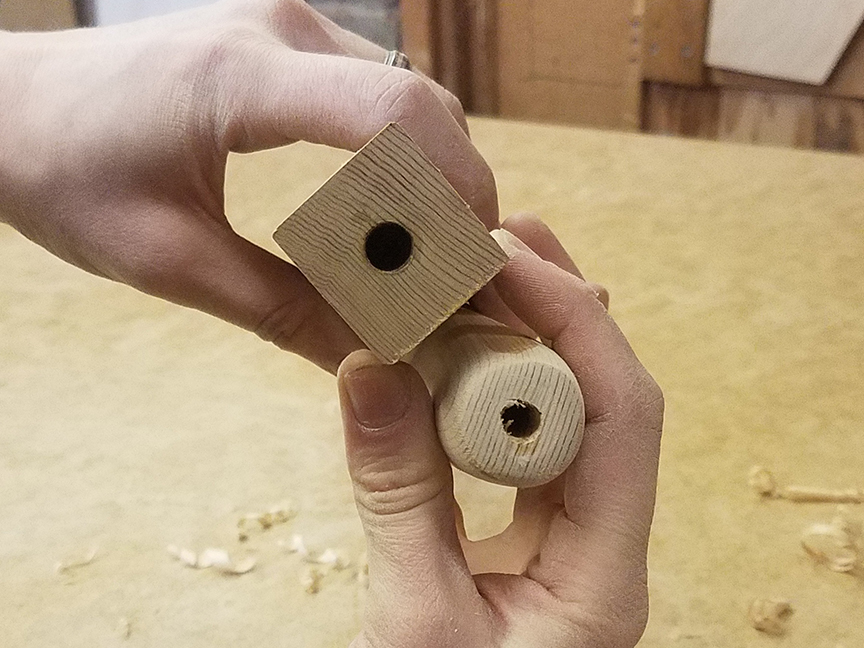

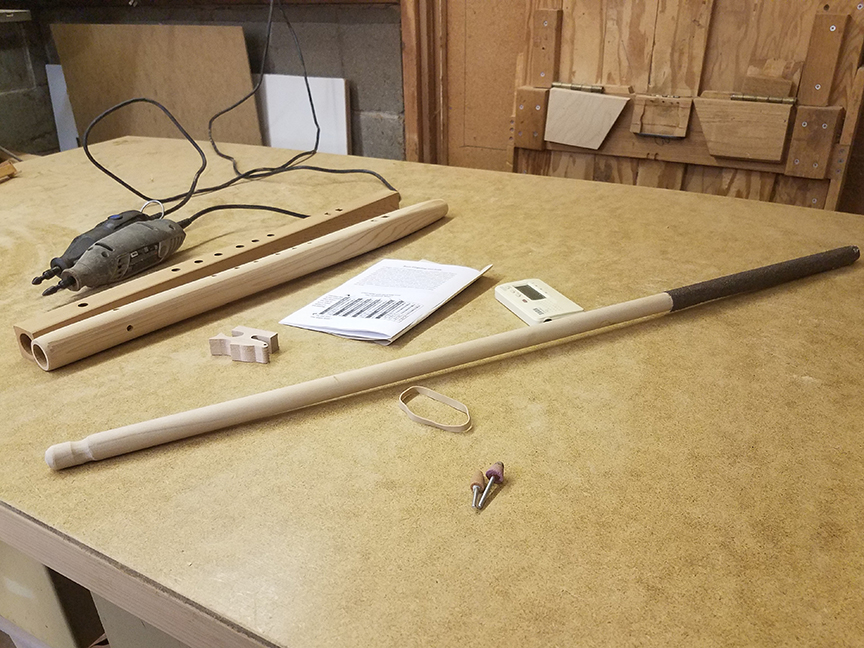

Supplies: Flute blank and block, Pre Bored Kit instructions, electric tuner, ½ inch dowel with 60 grit sand paper glued around it, rubber bands, Dremel with a cone shaped bit or something tapered to gradually enlarge each hole.

Your shop should be close to 72 degrees, the flute will tune flatter in cold weather and sharper in hot.

Put the block on with a rubber band and play the scale. Make a note of how the flute registers on the tuner. It will be very flat.

You will begin by enlarging all four direction holes gradually, sanding with your sanding dowel, and playing the flute for the tuner until the lowest note, all holes covered, plays in tune.

When you burn the holes, it pushes burs and debris down inside the bore, this will effect the tuning of the flute so you need to sand with a sanding rod before you check the tuning each time you enlarge a hole.

enlarge the next hole gradually, sand with the dowel and play for the tuner until it plays in tune.

You will repeat this until the flute is fully tuned.

STEP 6 | Finish sanding and varnishing

Supplies: Flute, varnish (oil based polyurethane recommended), paint brush, paper towels, squirt bottle (for Pre Bored Kit only)

Optional: drop cloth, shot gun swab

If you are making a flute from our Pre Bored Kit, you will need to sand the burn marks from tuning off before varnishing using 220 grit sandpaper.

If you have a Pre Tuned Kit, you don’t need to varnish the slow air chamber so you can skip this step.

Blow air through your flute’s blow hole to make sure there isn’t any debris in there. Using a small squirt bottle, cover the blowhole and squirt varnish inside the slow air chamber, cover fipple and blowhole and shake the flute to coat the inside then drain.

The flute will need to be coated inside 4 times and each time the varnish will need to dry overnight.

Now it is time to varnish the outside of your flute.

Use a brush to paint varnish on the outside of your flute and a shop paper towel to wipe off any excess varnish. Allow to dry. Sand lightly with 220 sandpaper and repeat until desired finish is achieved. We apply 4 coats of varnish.

If you would like to varnish the bore of the flute, use a shotgun swab dipped in varnish. (shot gun swabs are very useful for flute making! ) allow to dry , sand with your sanding rod if you like, and repeat until desired finish is achieved.

Now that you have a beautiful finished flute, why not do something creative with your flute block. You can do just about anything with your flute block: wood burning, carving, inlaying rocks or gems, but please remember that the groove in the bottom of the block is delicate and very crucial to the voice of your flute.

Put a few protective layers of varnish on your block and sit back and admire all your hard work.

Give your flute plenty of time for the varnish to dry before playing.

Final notes:

Tuning is hard, we get it. If your flute is not sounding right, send us an email and we will help. There are many factors at play when tuning: temperature, humidity, breath pressure, flute wall thickness, fipple length and width, and gremlins. Yep, I said it, sometimes even we don’t know why a flutes voice seems to suddenly change mid tuning.

We would really love to see your creations! Please email us a picture when you are finished!

Until next time, keep fluting!

-Lily

I would love to learn how to weave the banding or is that a trade secret? I have some boo boo’s to cover up.

LikeLike

Hey George,

It’s not a secret. I use cotton embroidery floss that’s run through bees wax. I also rub the area i am going to wrap with softened bees wax which has a bit of turpentine in it to keep it workable. The whipping is applied by making a loop and warping upwards towards the top of the loop, then when you are finished you pull the end you are working with through the loop and pull both ends to drag the knot under the wrap. Does that make sense? I think this same kind of wrap might also be used to make flys for fishing.

LikeLike

Lily: I like the weaving of the bands, I have done built fish rods , I have the j&p coats cotton embrdy floss(6 strand) do you use a single color, or 2 single colors twisted/ I’m trying hard to make them, or do you separate threads and add colors- your work is super! Thanks rd

LikeLike

Hi Rodger,

That thread should work great! I use DMC brand 6 strand embroidery floss. I use two contrasting colors and twist them together. I run the floss through bees wax that is softened with turpentine (melt then add turpentine to keep it soft and workable). The wax mixture is rubbed on the aera to be decorated as well which helps hold the floss in place.

My husband is very into fly fishing, do you actually make rods or just add the wrapping to them?

LikeLike

Thanks will try it , I made my first casting rod 30 yr ago from items from OKIE bug (Tulsa) I fly fish on mt fork river in se okla ( I have 2 RL Winston plus other rods) rainbow and brown trout-streams are like in your country thanks will try/ send pics when I master it / I am Cherokee bye rd

LikeLike

Lily: from Roger Dobson invoice 4308 my G flute, unable to make function. I have done troubleshoot many times , inspect inside, position block low breaths and harder / sound out of tune it’s not like the sound of your G flute video. I can’t play basic scale. Have exhausted my self/ what do you suggest? Nice beauty(just go to make it play) thanks

R

Dobson

LikeLike

Hi Rodger, I am going to respond via email right now

LikeLike